Why Upgrade to the Rekluse APEX Manual Clutch?

Following the success of its APEX clutch launch earlier this year, Race Winning Brands, the owner of Boise, Idaho based Rekluse, the designer and manufacturer of the new APEX clutch, has moved to add further industry experience to its V-twin sales and marketing team by hiring ex-PM and S&S man David Zemla.

Installs of the new system were a popular draw at its Black Hills Harley-Davidson set-up at the Sturgis Rally in August, and dealer traffic was strong at its booth at the recent Drag Specialties NVP and Product Expo in September.

Drag Specialties sales reps reported a thirst for a detailed understanding about how the APEX system differs from other clutch offerings, what the design benefits mean for the riding experience and how it adds to the V-win clutch options already established in the Rekluse range.

The biggest questions so far have been why a new clutch, and how does APEX add to the options available - after all, Harley clutch upgrades aren't exactly a new concept. Stock Harley clutches have never been one of the major design strengths of Milwaukee's Big Twin powertrain technology.

To answer these questions, Rekluse says that it is important to understand what type of clutch upgrade is best for the type of riding that an owner does and the feeling they want from their clutch - what are a rider's goals?

Rekluse says that clutch lever pull effort and lever feel are at the top of the list, with each style of clutch on the market, from extra plates to a slipper clutch to a lock-up clutch and everything in between, having its advantages.

"But our aim has been to innovate, to bring new ways of dealing with the problems often encountered with stock clutches, and to do it in new ways.

"Thanks to its proprietary design and patented components, APEX reduces clutch lever pull effort and improves modulation regardless of whether the bike is bone stock or built for all-out performance.

"We looked at clutch versatility in addition to lever pull effort. Baggers and other Harley models continuing to be increasingly asked to perform what used to be categorized as "Extreme Duty" where getting the power through the transmission concerned. Even 'street' clutches need new thinking to be able to keep up. The result has been that the compatibility of existing aftermarket and performance clutch options continues to become more segregated, leaving riders unsure of what's best for them.

"This all led us to the highly versatile solution that the APEX clutch design represents. An all-performance capable manual clutch system that will help riders get the most out of their engines, regardless of their riding style or other performance upgrades.

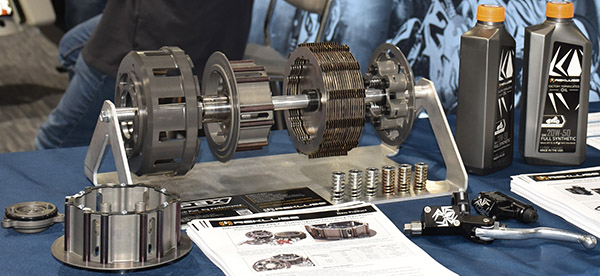

"This versatility is achieved as a result of a meticulously tuned and tested system that features a slew of proprietary clutch technology, starting with the Fixed-Pin Hub.

"Traditional hub designs use machined grooves in the aluminum to retain drive plates, commonly causing notching inside the grooves through normal use and eventually leading to hub replacement. Fixed-Pin is a patented new hub design exclusively from Rekluse that uses steel-on-steel contacts to retain the drive plates to eliminate that notching wear and the performance degradation that comes along with it. As an added bonus, it also provides a noticeable improvement in the clutch modulation and control that riders can feel at the lever.

"Our award-winning TorqDrive friction disc technology allows for up to eight additional friction discs over the OEM clutch stack. This additional plate capacity is a major factor in allowing the clutch lever modulation to remain easy throughout various power levels and rpm ranges. Plus, at the end of the day, more friction discs equals more torque capacity and therefore improved power transfer to the rear wheel.

"This is true whether the engine is stock, has bolt-on upgrades, or is an all-out high-hp build pumping out 200 ft.-lbs.

"The Rekluse TorqDrive for Harley clutches in our APEX clutch uses two sets of clutch springs - six clutch springs in total - but each APEX clutch system is supplied with two different sets of springs. These differing spring rates, one stiffer and one softer, allows riders to tune their clutch system with a total of three spring rate combinations, depending on the torque output of the engine and rider's clutch feel preference.

"In addition to the Fixed-Pin hub, APEX is also supplied with a billet, hard-anodized pressure plate. These billet internal components, referred to as 'Core' components, help maximize durability through both the strength of the parts themselves, and with their oil flow improving designs, increasing oiling throughout the clutch. This helps keep the heat down and allows the entire clutch system to perform longer and more consistently.

"Although available without a complementary clutch basket upgrade, for those who wish to keep the OEM basket, Rekluse recommends the new basket for maximum durability. APEX is supplied with basket sleeves that simply slide in between the basket tangs and protect them from notching.

"Essentially, the APEX clutch is a manual clutch system that takes the capabilities of a traditional coil spring clutch to a completely new level. This clutch is an innovative system that uses a combination of proprietary technology and design, including Fixed-Pin, TorqDrive and Core. APEX improves lever feel, power delivery, rideability, longevity and torque capability, just to name a few of the benefits that we are seeing."

Rekluse says that APEX is available for a wide range of Harley-Davidson models powered by Twin Cam and Milwaukee-Eight (M-8) big twin engines, covering year models from 2007 to current. APEX is available from Rekluse distribution partners, including Drag Specialties.

REKLUSE MOTOR SPORTS